India’s only Center of Excellence (COE) Solution Provider

CENTER OF EXCELLENCE

BENEFITS OF COE FOR STUDENTS & PROFESSIONALS

• Hands-on experience

• Enhanced understanding of EV components

• Exposure to emerging technologies

• Contribution to sustainability

• Opportunities for innovation

• Generation of skilled and future-ready workforce.

• Developing acquaintance of faculties and trainers with Electric Vehicle Technology.

• Promote the spirit of entrepreneurship and enable the students & faculties to start their own startups & companies.

• Nurturing research fellows & enabling them to publish research papers, intellectual property, trademarks & patents.

OBJECTIVE OF OUR E-MOBILITY CoE

The ultimate goal of our E-Mobility CoE is to help individuals become knowledgeable and skilled in electric vehicle technology, thereby, contributing to advancement in field of electric vehicle technology. We are aimed at providing individuals with a practical, hands-on learning experience in electric vehicle technology and developing skills in areas such as EV design, battery pack design, manufacturing, and maintenance. For the development of EVs, more scope has to be generated in the research and innovation and our CoEs can become an effective tool to foster that.

ABOUT SKYY RIDER ELECTRIC'S CoEs

At Skyy Rider Electric, we believe, to create a sustainable future, nurturing the next generation of Electric Vehicle professionals is highly essential. Being an EV Manufacturing company, we are committed to advancing the field of electric mobility through constant innovation, research, and development.

Skyy Rider Electric’s Centre of Excellence, hence, is primarily targeted at making those skilled professionals who can help propel the pace of development and innovation in the field of electric mobility technology.

With our decade-long experience, we’re setting up the modern E-Mobility Centre of Excellence (CoEs) aimed at imparting not only theoretical knowledge but also hands-on exposure to familiarize young minds with the ever-evolving field.

Our CoEs are state-of-the-art facilities designed to support and test cutting-edge technology. They’re equipped with the latest tools and technologies used in the development and testing of electric vehicles, including test rigs, and other equipment used in the production of electric vehicle components and systems.

WHY CENTER OF EXCELLENCE ?

• Skill development & practical based learning.

• Bridge the gap between industry demands & supply from academia.

• Enabling more research & innovation opportunities.

PRODUCT CATALOGUE

TESTIMONIALS

OUR ACADEMIC PARTNERS

KEY MILESTONES

WHAT WE OFFER ?

E scooter design and manufacturing kit

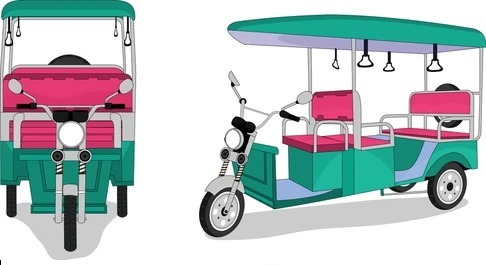

E rickshaw design & manufacturing kit

Golf cart design and manufacturing kit

Urban mobility lab

Micro mobility lab setup

Advance E -Mobility lab

OUR PRESENCE